Wet-type Intense Magnetic Separator

HYG seres wet-type Intense Magnetic Separator

- Product Description

-

- Commodity name: Wet-type Intense Magnetic Separator

- 计费重量: 1

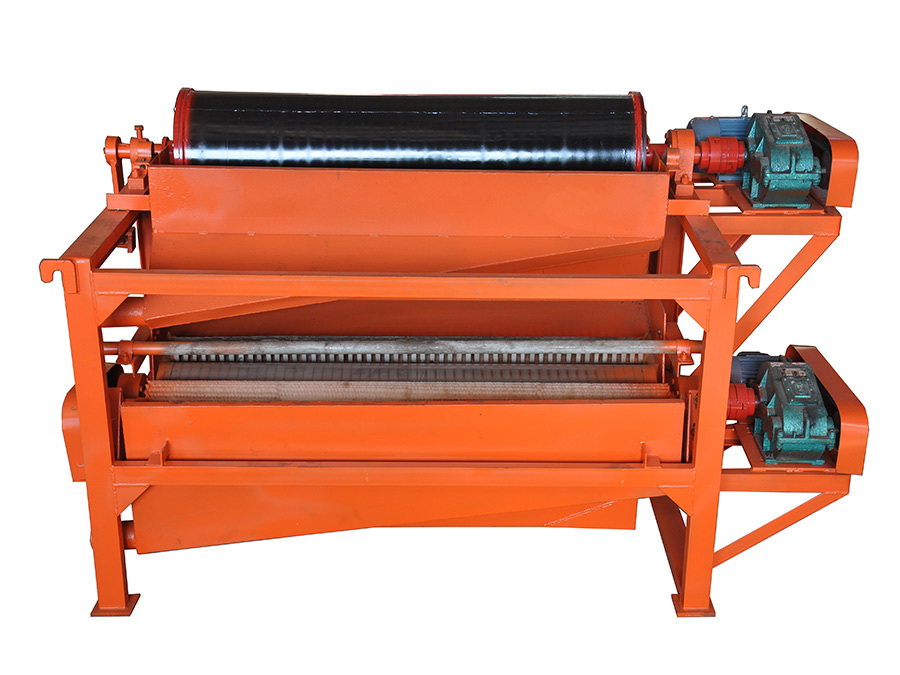

Roller-Type High-Intensity Wet Magnetic Separator This separator is a roller-type high-intensity wet magnetic separator specifically designed to address the challenges of separating fine-grained weakly magnetic minerals. The magnetic system of the roller-type unit features a 360-degree magnetic configuration, with unique innovations primarily in the ore discharging method. It adopts a high-pressure water pulse flushing system for discharge.

Roller-Type High-Intensity Wet Magnetic Separator This separator is a roller-type high-intensity wet magnetic separator specifically designed to address the challenges of separating fine-grained weakly magnetic minerals. The magnetic system of the roller-type unit features a 360-degree magnetic configuration, with unique innovations primarily in the ore discharging method. It adopts a high-pressure water pulse flushing system for discharge.

Given the inherent characteristic that weakly magnetic iron ores such as hematite and limonite are always associated with a small amount of magnetic iron, and to prevent this minor magnetic iron content – along with mechanical iron introduced during production processes like crushing and ball milling – from being adsorbed by the high-intensity magnetic rollers, accumulating on the roller surface, blocking the magnetic circuit, and reducing the adsorption magnetic field strength of the rollers, the traditional brush method is insufficient. Brushes struggle to effectively remove this portion of magnetic iron and are prone to rapid wear, which reduces their discharge efficiency.

Therefore, the machine specifically employs a high-pressure water pulse discharge device. This device is an industry innovation and patented technology that conserves water usage, avoids the wear issues associated with traditional brushes, and crucially protects the magnetic blocks on the roller surface from direct abrasion by brushes, thereby extending the equipment's service life.

Machine Models and Applications Based on the processed ore type, the machine is available in two tank structure forms: co-current type and semi-counter-current type. The magnetic wrap angle is 360 degrees, and the magnetic field strength can be selected within the range of 10,000 to 14,000 GS. Our company can manufacture corresponding multi-roller combined models according to customer beneficiation process requirements. Conventional combinations include: single or double roller high-intensity magnetic separation, one-drum double-roller high-intensity magnetic separation, and one-drum double-roller high-intensity magnetic separation plus single roller cleaning, etc. Applications:• Primarily used for the fine-grained tailing discard or concentration and purification of fine-grained weakly magnetic minerals (e.g., limonite, manganese ore, titanium ore, etc.). • Refined processing (removal of impurities like iron and titanium) of raw materials and products of non-metallic minerals (e.g., andalusite, sillimanite, kyanite, garnet, feldspar, quartz, zirconite, corundum, diamond, etc.). • Removal of weakly magnetic harmful impurities from various abrasive products, catalysts, and other materials.

Specification

Model

Cylinder size(mm)

Magnetic Field

Speed(r/min)

Feeding size(mm)

Capacity(T/h)

Power(KW)

Weight(T)

HYG1606

Φ160×600

11000

70

0.5-3

0.5-1

1.1

0.25

HYG1608

Φ160×800

11000

70

0.5-3

0.6-1.2

1.1

0.3

HYG1610

Φ160×1000

11000

70

0.5-3

0.8-1.5

1.1

0.45

HYG1612

Φ160×1200

11000

70

0.5-3

1-2

1.5

0.6

HYG2210

Φ220×1000

12000

60

0.5-3

1-2

1.5

0.6

HYG2212

Φ220×1200

12000

60

0.5-3

2-3

1.5

0.8

HYG2215

Φ220×1500

12000

60

0.5-3

5-7

1.5

1.1

HYG2218

Φ220×1800

12000

60

0.5-3

8-13

1.5

1.3

HYG2610

Φ260×1000

13500

60

0.5-3

3-5

1.5

1

HYG2612

Φ260×1200

13500

60

0.5-3

5-7

1.5

1.1

HYG2615

Φ260×1500

13500

60

0.5-3

8-10

1.5

1.3

HYG2618

Φ260×1800

13500

60

0.5-3

10-15

1.5

1.8

HYG2620

Φ260×2000

13500

60

0.5-3

12-18

2.2

2.1

HYG3010

Φ300×1000

13500

55

0.5-3

5-7

1.5

1.1

HYG3015

Φ300×1200

13500

55

0.5-3

10-15

1.5

1.8

HYG3018

Φ300×1800

13500

55

0.5-3

12-18

2.2

2.1

HYG3022

Φ300×2200

13500

55

0.5-3

15-20

2.2

2.6

HYG3025

Φ300×2500

13500

55

0.5-3

17-22

3

3

HYG3815

Φ380×1500

13500

55

0.5-3

12-18

2.2

2.5

HYG3818

Φ380×1800

13500

55

0.5-3

17-22

2.2

2.8

HYG3822

Φ380×2200

13500

50

0.5-3

18-25

3

3

HYG3825

Φ380×2500

13500

50

0.5-3

20-27

3

3.5

HYG5015

Φ500×1500

13500

45

0.5-3

17-22

3

2.9

HYG5018

Φ500×1800

13500

45

0.5-3

18-25

4

3.2

HYG5025

Φ500×2500

13500

45

0.5-3

20-30

4

3.8

HYG5028

Φ500×2800

13500

45

0.5-3

22-33

4

4.3

Key words:- 湿式强磁磁选机

- 梧州市华磁矿山设备有限公司

- 梧州市华友磁选机厂

- 专注磁选机智造

- 专业磁选机设备研发制造商

Keywords:

Wuzhou Huaci Mining Equipment Co., Ltd.

Wuzhou Huayou Magnetic Separator Plant

Specializes In Magnetic Separator Manufacturing

Professional Magnetic Separator Equipment R&D Manufacturer

Previous

Recommended Products