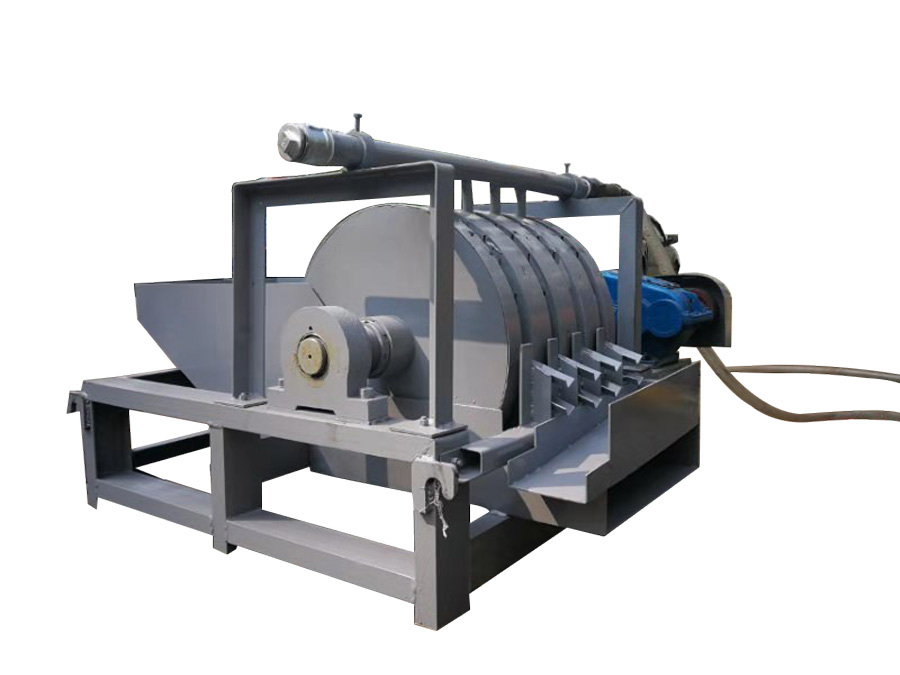

Disc Type Tailings Recovery Machine

Disc Type Tailings Recovery Machine

- Product Description

-

- Commodity name: Disc Type Tailings Recovery Machine

- 计费重量: 1

This equipment features high recovery efficiency, compact size, easy arrangement, large processing capacity, and significant economic benefits. It is specially designed for the re-processing of discarded tailings, extracting valuable minerals from waste to reduce environmental pollution.

Model Introduction:

This equipment features high recovery efficiency, compact size, easy arrangement, large processing capacity, and significant economic benefits. It is specially designed for the re-processing of discarded tailings, extracting valuable minerals from waste to reduce environmental pollution. The equipment can be used for:Direct recovery of iron concentrate from magnetic separation plant tailings.Recovery of iron scale from steel rolling mill wastewater.Extracting iron concentrate from tailings accumulated over many years.Separating iron ore from inland riverbeds or coastal placer deposits.Effectively recovering weakly magnetic minerals such as oxidized iron ore, titanium ore, manganese ore, and limonite.

Model Features:

1.Easy Installation: The disc-type tailings recovery machine has a compact structure, requires minimal installation space, and features a small feed and discharge height difference. It can be installed in most areas with tailing chutes or discharge channels.

2.High Recovery Rate: All material passing between the magnetic disks is subjected to the magnetic field, ensuring full recovery of magnetic minerals with high efficiency.

3.Large Processing Capacity: Specifically designed for tailings reprocessing, the machine features a vertical open-top trough structure, enabling it to handle large volumes of low-grade tailings.

4.Water Saving: Due to the large contact area between the magnetic disks and the slurry, the recovered magnetic minerals contain a significant amount of water. The discharged minerals remain in a fluid state, allowing the unloading process to be completed with little or no additional water.

Specification

Model

Specifications

Processing Capacity (T/H)

Power (KW)

Number of Magnetic Disk Sets

Surface Magnetic Field (GS)

8004

Φ800×4

100

2.2

4

6000-1200

8006

Φ800×6

150

3

6

6000-1200

8008

Φ800×8

200

4

8

6000-1200

8010

Φ800×10

240

5.5

10

6000-1200

8012

Φ800×12

260

5.5

12

6000-1200

1008

Φ1000×8

240

5.5

8

6000-1200

1508

Φ1500×8

280

7.5

8

6000-1200

1510

Φ1500×10

300

7.7

10

6000-1200

1512

Φ1500×12

320

11

12

6000-1200

Key words:- 盘式尾矿回收机

- 梧州市华磁矿山设备有限公司

- 梧州市华友磁选机厂

- 专注磁选机智造

- 专业磁选机设备研发制造商

Keywords:

Wuzhou Huaci Mining Equipment Co., Ltd.

Wuzhou Huayou Magnetic Separator Plant

Specializes In Magnetic Separator Manufacturing

Professional Magnetic Separator Equipment R&D Manufacturer

Recommended Products